Index

- Metrology Lab by Hioki

- Dynamic impedance testing solutions

- Insulation evaluation testing solutions

- Automatic partial discharge (RPDIV) using impulse voltages as defined in IEC 61934

- Partial Discharge Testing of Motor Stators Using an Impulse Tester and Oscilloscope

- Partial Discharge Testing of Motor Stators Using a Withstand Voltage Tester and Oscilloscope

- Automatic impulse testing of motor stators using high-voltage relays

- IEC 60851-5 Winding Wire Dielectric Tangent (tanδ) Testing

- Testing of Dielectric Constant and Dielectric Loss Tangent Temperature Characteristics in Electrical Insulating Materials

- Equipment at Metrology Lab

- New Arrivals

- Inquire

Metrology Lab by Hioki

Trends in power electronics products are moving in the direction of high voltage and high current. Many of our customers’ requests stem from high voltage and high current environments.

Metrology Lab, run by Hioki, is a market leader in two evaluation methods: electrical insulation evaluation and dynamic impedance. Needs for these topics are increasing due to recent evolution of power electronics. Our goal is to establish new evaluation technology and disseminate solutions.

Please use the form at the bottom of the page for inquires about the solutions posted on this site, to consult about these topics, and to request sample tests.

Dynamic impedance testing solutions : Fuel cells, electrolyzers for hydrogen production, power electronic components such as capacitors and coils

Insulation evaluation testing solutions : Insulation test / partial discharge test of motors, power modules, and electrical insulation materials

Dynamic impedance testing solutions

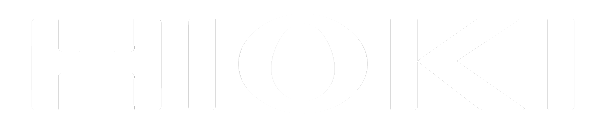

DC Current Superposition Testing of Coils Using a Power Analyzer

We certified that a Power Analyzer can be used to perform high-accuracy DC current superposition testing (DC current bias testing) of high-current coils.

Insulation evaluation testing solutions

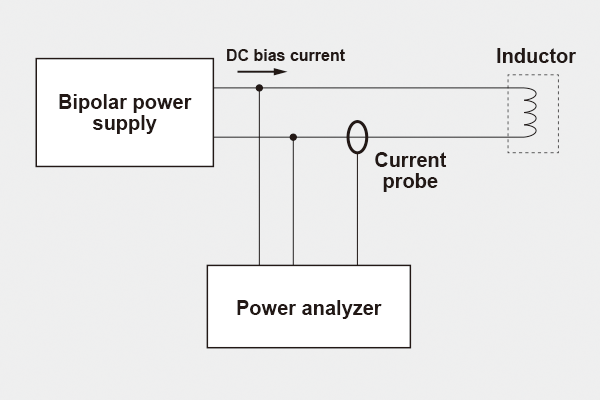

Automatic partial discharge (RPDIV) using impulse voltages as defined in IEC 61934

With conventional impulse testers, it is difficult to automatically perform partial discharge (RPDIV) testing as defined in IEC 61934. Sequence Maker, a free Excel add-in, quickly creates programs that make it possible to automate such testing.

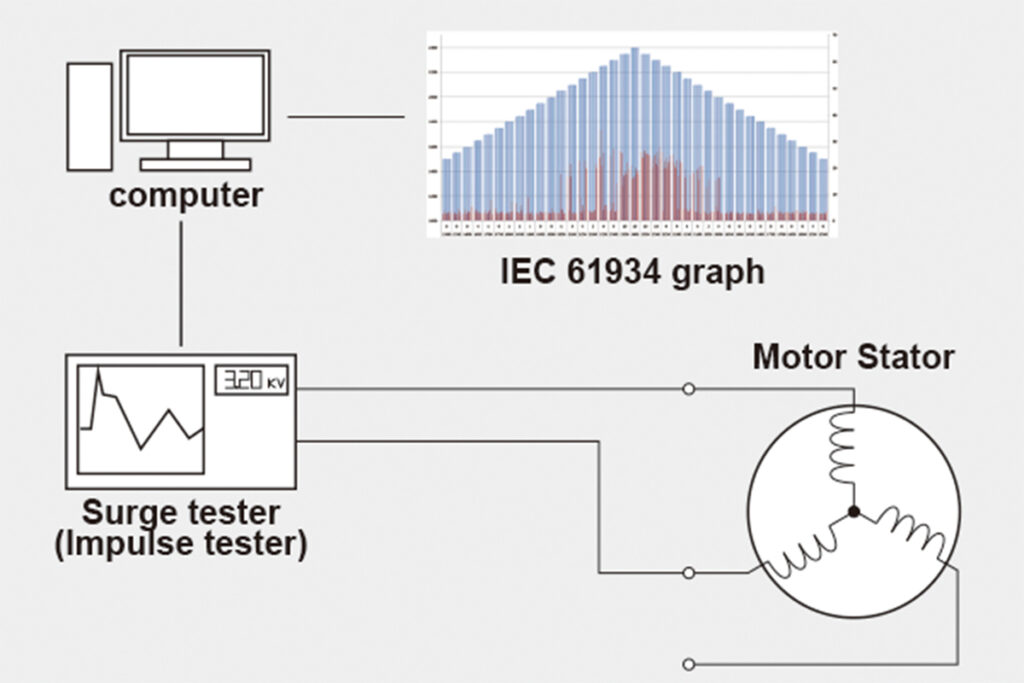

Partial Discharge Testing of Motor Stators Using an Impulse Tester and Oscilloscope

It’s possible to check for insulation defects in motor stators by observing current waveforms during impulse testing. If there are insulation defects between coils, partial discharges will occur at a lower voltage.

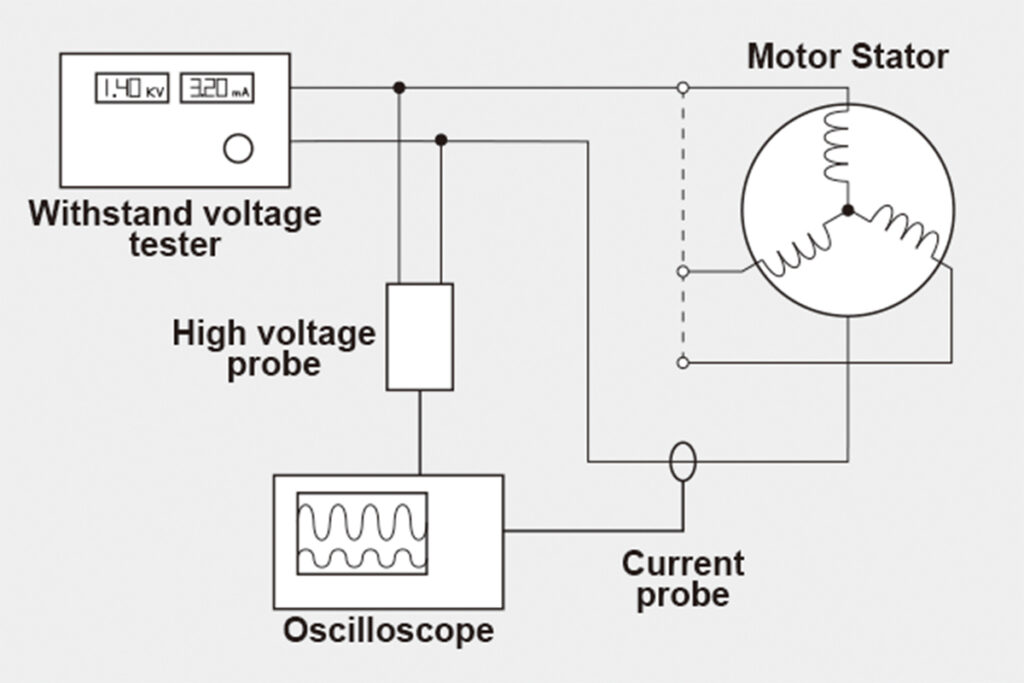

Partial Discharge Testing of Motor Stators Using a Withstand Voltage Tester and Oscilloscope

It’s possible to check for insulation defects in motor stators by observing current waveforms during withstand voltage testing. If there are insulation defects between a coil and the core, partial discharges will occur at a lower voltage.

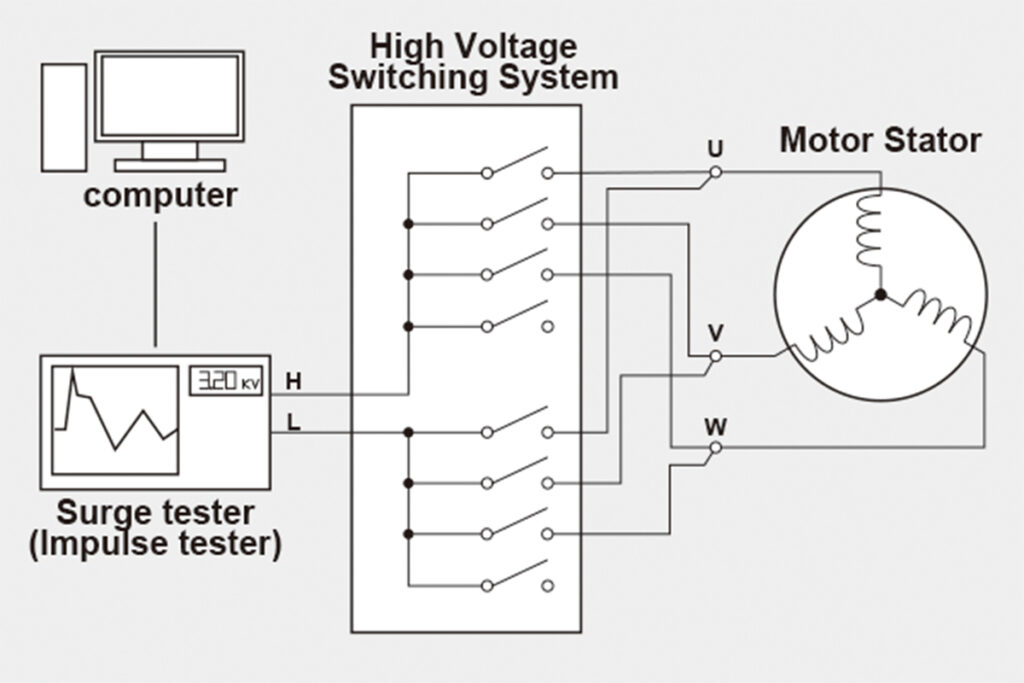

Automatic impulse testing of motor stators using high-voltage relays

When the test voltage for impulse testing of motor stators exceeds 1500 V, it becomes difficult to obtain relays for use in switching test circuits. Consequently, such tests rely on manual measurement or manual switches. This application proposes an approach for automating impulse testing of stators.

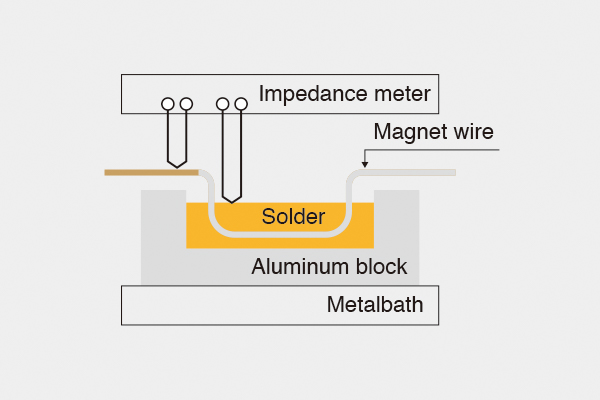

IEC 60851-5 Winding Wire Dielectric Tangent (tanδ) Testing

Enamel wires are used in motor windings. As part of R&D and product inspections by enamel wire manufacturers as well as acceptance inspections and material development by motor manufacturers, engineers test the performance of enamel wire by measuring its dielectric tangent (tanδ) as set forth in IEC 60851-5.

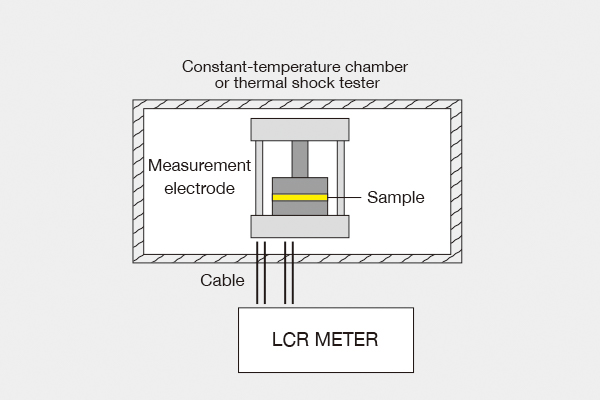

Testing of Dielectric Constant and Dielectric Loss Tangent Temperature Characteristics in Electrical Insulating Materials

Demand is growing for the ability to test the dielectric constant and dielectric loss tangent of electrical insulating materials used in EV and power electronics applications in high-temperature environments. Measurement electrodes from KEYCOM can be combined with Hioki’s LCR meters to meet this need.

Equipment at Metrology Lab

A list of measuring instruments owned by Metrology Lab. Measuring instruments not on the list can be prepared if they are Hioki product.

| Measuring instrument name | Model / Manufacturer | Application example |

| Power analyzer | PW6001 / Hioki | Impedance measurement of batteries, fuel cells, and water electrolysis cells for hydrogen production |

| High precision current sensor | Various / Hioki | For impedance measurement, DC/AC current measurement |

| Bipolar power supply | Various / manufacturers | Charging/discharging device, DC/AC power supply, measurement power supply |

| High accuracy resistance tester | RM3545 / Hioki | For resistance measurement |

| LCR meter | IM3570 / Hioki | LCR measurement, measurement signal level / frequency sweep |

| Withstanding voltage / insulation resistance tester | 3153 / Hioki | AC DC withstand voltage test, insulation resistance test |

| Impulse tester | ST4030A / Hioki | Interlayer short circuit detection test, partial discharge test |

| Digital oscilloscope | MDO4000 / Tektronix | Partial discharge waveform for observation |

| High voltage probe | Various / manufacturers | Partial discharge waveform for observation |

| High frequency current probe | Various / manufacturers | Partial discharge waveform for observation |

New Arrivals

| Release date | Contents |

| May 10, 2022 | IEC 60851-5 Winding Wire Dielectric Tangent (tanδ) Testing |

| May 10, 2022 | Testing of Dielectric Constant and Dielectric Loss Tangent Temperature Characteristics in Electrical Insulating Materials |

| October 21, 2021 | DC Current Superposition Testing of Coils Using a Power Analyzer |

| October 12, 2021 | Automatic impulse testing of motor stators using high-voltage relays |

Inquire

Terms of use

By providing my personal information, I agree that Hioki may use it for the purposes stated in its Privacy Policy. I also agree that my personal information may be shared with Hioki subsidiaries and our distribution partners, in particular sales and rental partners, in order to fulfill said purposes. This consent is based on my free decision and I may withdraw my consent at any time. Upon receipt of my declaration of withdrawal, my personal information may no longer be processed and shall be deleted without undue delay. The withdrawal of my consent shall not affect the lawfulness of processing based on my consent before the withdrawal.

I may declare my withdrawal by contacting the following:

Manager Administration Division

HIOKI E.E. CORPORATION

81 Koizumi, Ueda-shi, Nagano 386-1192

Phone: +81-268-28-0550

日置電機株式会社 個人情報の利用規約

私が入力した個人情報を、プライバシーポリシーの利用目的の範囲で、HIOKIが使用することに同意します。また、利用目的を実現するために、HIOKIの販売子会社及び流通パートナー、特に販売代理店とレンタル会社へ個人情報を提供することに同意します。この同意は私の自由な決定に基づいており、いつでも同意を取り下げることができます。HIOKIが私の脱退宣言を受領する場合は、私の個人情報は使用されなくなり、過度の遅延なく削除されるものとします。私の同意の撤回は、撤回前の私の同意に基づく処理の合法性に影響を与えません。

以下の連絡先に同意の撤回を宣言することができます。

日置電機株式会社 総務課 個人情報担当〒386-1192 上田市小泉81番地 TEL 0268-28-0550